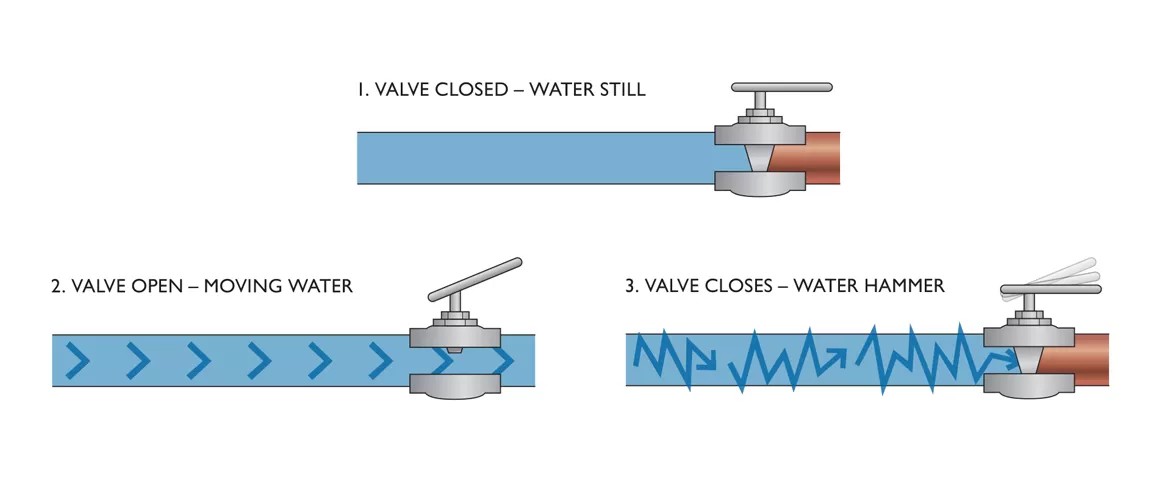

Water is a phenomenon that can happen in any piping system where media flow is managed by valves. A pressure wave may be produced by the water's momentum when valves close or an acting pump abruptly stops. This wave travels back up the pipe after bouncing off the closed port. This phenomenon is made worse when the transient pulse's frequency reverberates with the system's pipes or existing standing waves, which have the potential to build up to the point where they can cause significant harm.

Reasons for Water Hammer

A lot of us have heard pipes bang when the tap is turned off. Actually, you're probably reading this guide right now for that reason! There are several possible causes of water hammer, all of which are explained below.

Pipes that are loose

Shock waves within the pipework are likely to be worsened by the physical banging of the pipe itself if pipes are not properly secured, or if they have come loose entirely. For years to come, pipes should be fixed firmly to strong materials to maintain their rigidity. Check inside cabinets and beneath floorboards. These pipes still need to be maintained even though they are hidden!

Damaged stop valves

Stop valves, also called stopcocks, can produce water hammer if their gland packing is missing or their washers are worn. The water hammer's shock waves have the potential to knock the valve handle and valve jumper since stop valves are nearly always open during this event.

Trapped air

One of the most common causes of water hammer is trapped air within the system. Filling empty pipework too quickly can allow air to enter your system. Make sure the pipework is filled gradually to allow air to escape in order to reduce the possibility of air building up within the system.

As an alternative, trapped air can be released by using air-relief valves. These valves are positioned high on the system.

Ball-float valves

When a ball or float valve is used to regulate the inflow and outflow of water, ripples within the tank can cause water hammer. The valve float can rock up and down, opening and closing the valve as water enters the sealed tank. The hammer sound can be produced by this movement by generating a pressure wave that reverberates through the pipework. Metal plates can be added to plastic tanks to stiffen their structure and lessen the amount of flexing that occurs.

Quick-acting valves

Fast-acting valves are another common cause of water hammer. Water is instantly stopped by fact-acting valves, like electronically controlled solenoid valves, which causes water shock waves to rebound up the pipework.

The Impact of Water Hammer

Water hammer may seem and sound harmless, but if you ignore it, your pipework system may suffer serious damage. The following are possible ways that water hammer's long-term effects could manifest themselves:

1.Leaks: Water hammer can harm fittings, joints, and connections, which can lead to inadequate seals and eventually leaky pipes.

2.Burst pipes: Repairing burst pipes brought on by accumulated pressure can be very costly. Owing to the nature of the repair, a significant replacement procedure is frequently required.

3.Property damage: Unnoticed leaks run the risk of causing nearby electrical equipment to sustain damage or corrode infrastructure. Consider the rotting of the foundation and/or support beams, as well as electrical cabling.

4.Downtime: The financial cost of the system's or the building's complete downtime (if it's a commercial building) must be taken into account if significant damage is done to it.

Ways to Avoid/Stop Water Hammer

Wrap and secure any loose pipes.

Verify that all pipes are properly fastened to their surroundings with robust fasteners. To add even more support, pipe straps can be added, but the material choice for them should be carefully considered. Certain metals can corrode and react chemically with one another, which can cause poor fitment later on. Some others may expand at different rates when heat is applied, leading to an inadequate fit.

In order to absorb the inner shock waves, pipes can also be wrapped in foam insulation.

Install air-relief valves

Entrapped air can escape through air-relief valves, which are positioned at high points throughout a pipework system. Air-relief valves should be positioned early in the system, midway through the system, around pumps, and downstream in situations where the system is dispersed over a sizable level area. Another useful alternative to the water hammer is an air chamber. These systems are made up of a brief section of pipe that has an air-filled or empty chamber to absorb shock waves. As a result, the shock waves downstream of the valve are smaller. It's important to remember, though, that in order to maintain these air chambers' continued efficacy, the water must be drained out of them every few months.

Install arrestors for water hammers.

Air chambers and water hammer arrestors function similarly. Water hammer arrestors, on the other hand, use a combination of springs and air bladders to absorb water movement and lessen shock waves downstream of quick closing valves in place of a vertical pipe that absorbs pressure. Water arrestors are a more costly long-term solution to water hammer because they don't need to be maintained like air chambers do.