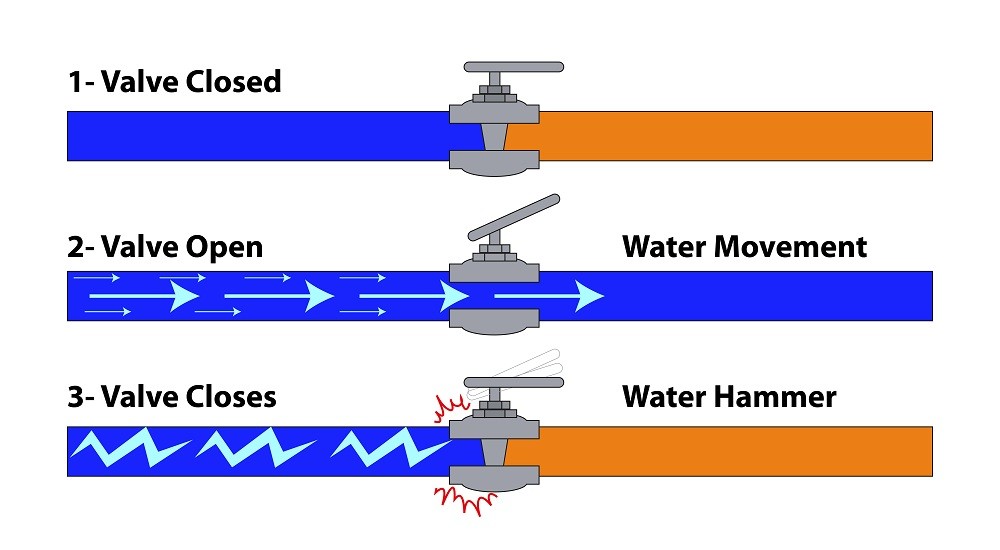

The peak pressure associated with water hammer is proportional to the volume, similar to what happens when a non-compliant object collides with a wall at high speed. For instance, a pipeline that is 24 inches in diameter and 50 kilometers long, filled with water, has a mass of approximately 16,000 tons. Any disruption to the momentum of such a substance requires a significant amount of energy.

Therefore, in large pipelines, this phenomenon can lead to catastrophic damage, ranging from vibrations and noise to the complete collapse of the pipeline.

Water hammer can be prevented or lessened using a variety of techniques, all of which rely on preventing abrupt changes in fluid flow or safely dissipating wave energy without endangering the system. Because of the way they are made, valves are essential to this phenomenon because they can change the direction of fluid. A key component of creating a pipeline system that works well is making sure all of the valves are operating properly.

How Do Valves Work to Prevent or Reduce Water Hammer?

1. Extend the period of closure

Increasing the period of time that fluid motion changes is a useful strategy. This is frequently accomplished in pipelines by extending the valve closure time, which permits energy dissipation from pressure loss. The link between the pressure differential at the valve's ends and the flow through the valve indicates how much a closed valve's flow capacity decreases. The higher the closure rate at a particular flow rate, the lower the flow and the larger the pressure differential for a given flow. The time it takes to close the valve is correlated with the pressure peak that is produced. The greatest pressure peak is produced by an instantaneous valve closure. Even though incredibly slow valve closure might seem to completely eliminate water hammer, it isn't always practical or appropriate for all applications.

Especially in emergency shut-off valve applications, valves in isolation or shut-off valve applications need to function as fast as possible. This is done to quickly stop the fluid flow as well as to prevent corrosion-related damage to closing membranes, valve seats, and other components if open/closed valves are left partially open for prolonged periods of time. Using a two-speed or variable-speed system to operate valves can help solve this problem. With the help of these systems, operators can close the valve quickly—for instance, by closing 80% of it at first and then progressively closing the remaining 20%—in order to release the most energy in the shortest amount of time. This method can effectively block the flow while taking into account the required pressure loss to lessen or eliminate water hammer. It can do this quickly by drastically reducing the flow of the valve.

The actuator's operation control device is dependent on the energy supply system and valve position feedback for system management. Limit switches or position sensors are usually used to synchronize the target position setpoint in simple hydraulic actuator systems or systems that use non-compressible fluids. The system lowers the flow to shorten the actuator's stroke time once the valve has reached the desired position. Systems that use compressible fluids or pneumatic systems can be designed with similar configurations for operation. A transmission analysis of the pipeline system is used to calculate the amount of time needed to change the fluid in the pipeline.

2. Lower the velocity of the flow

Intentionally lowering the fluid's flow rate inside the pipeline is another popular method for lessening the potentially harmful effects of water hammer. This speed in turn depends on the pipeline's nominal diameter. Understanding this relationship is essential to solving the problem because it means that as the pipeline diameter grows, the fluid can flow through a wider cross-sectional area. Consequently, in a pipeline with a larger diameter, the fluid must flow at a slower speed to maintain a constant flow rate. On the other hand, a smaller diameter pipeline requires the fluid to flow faster in order to maintain the same flow volume.The fluid's kinetic energy increases with its velocity, making the pressure fluctuations brought on by abrupt changes more noticeable.

Because of this, selecting the pipeline diameter becomes crucial for the design. Smaller pipelines may seem like the best option to achieve the theoretical minimum flow rate requirements, but in reality, this strategy frequently results in higher flow velocities. The susceptibility to water hammer during valve operation or other flow interruptions is thereby made worse by these increased velocities.

Consequently, choosing a pipeline diameter greater than the minimum diameter determined by flow calculations is a wise and proactive move. The flow velocity naturally decreases at the same flow rate when larger pipelines are used. By acting as a buffer, this decrease in velocity enables more gradual adjustments to pressure and flow. As a result, there is a decreased chance of pressure peaks and the related system damage risks.

In summary, pipeline valve drive systems must be properly designed in order to avoid or lessen the effects of water hammer in pipeline systems. Valves have an impact on the fluid's momentum inside the pipeline by reversing the direction of flow. Valves may need to make these adjustments quickly depending on the application, but doing so quickly can increase pressure peaks and amplify pressure waves. Water hammer problems in pipeline valve operations can be effectively resolved by incorporating a variable-speed system for valve operation into the pipeline system design, together with thorough fluid transmission analysis and consideration of future flow increments.