Large-scale processing applications requiring fast, leak-proof opening and shutting employ butterfly valves. A particular kind of butterfly valve designed to address the drawbacks of other butterfly valve types is the triple offset butterfly valve. It is the most advanced butterfly valve by design and is capable of operating in any processing conditions, including those with high temperatures and pressures that other butterfly valves simply cannot withstand.

The valve can endure wear and tear and keep its leak-proof sealing integrity for a much longer period of time thanks to triple offset technology. Because it can tolerate high pressure and temperature levels and is low maintenance and reasonably priced, this makes it an essential valve for processes.

To assist you in choosing the best valve for your application, we'll go over the benefits and characteristics of the triple offset butterfly valve in this post.

What Makes The Triple Offset Butterfly Valve Different?

The triple offset butterfly valve is a superior option to other valves in your application for a number of reasons. These are the main characteristics it provides:

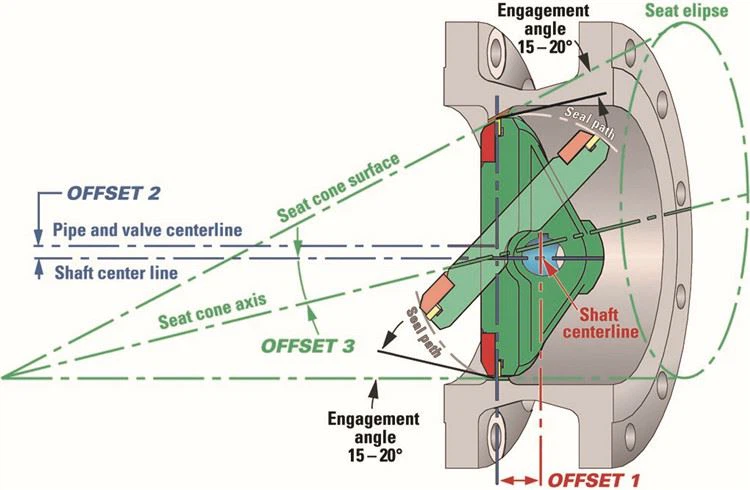

Triple offset butterfly valves are designed so that disc and seat positioning controls opening and closing, as opposed to rubber rubbing or seat/body contact. Reduced torque lengthens the metal's and other parts' lifespan by reducing wear and tear on them.Additionally, because less torque is needed to move the valve disc, the valve can open and close faster. Triple offset butterfly valves, which have a Stellite 21 + 316SS harden Disc Edge overlay, provide better sealing than other butterfly valve varieties. This makes the sealing surface harder in order to stop leaks even at high pressures. To ensure that the seats for triple offset butterfly valves can withstand high pressure and temperatures, Inconel 718 and graphite are pressed against a Stellite + 316SS overlay on the disc edge. Butterfly Valves' triple offset butterfly valves are resistant to temperatures ranging from -320 degrees Fahrenheit to 1,022 degrees Fahrenheit. Their ANSI 50/300/600/900 pressure rating makes them safe and perfect for use in power plant systems. The third offset is an angular offset that reduces friction when the valve disc opens and closes. When there is no friction, there is no material rubbing against one another, which shortens the valve's lifespan and improves performance. Triple offset butterfly valves are more expensive, but their construction requires fewer materials. Their extended lifespan and minimal maintenance needs render them an extremely economical variety of butterfly valves.

The advantages of this technology result in reduced maintenance needs and longer service times. A longer-lasting valve will lower system downtime and save costs. JONLOO Butterfly Valves guarantees 50,000 cycles out of their triple offset butterfly valves without packing adjustment. Triple offset butterfly valves are robust enough to tolerate high pressure levels without leaking, making them fire-safe and temperature-resistant. They are therefore the ideal choice for applications requiring power generation, such energy power plants. Additionally, they are a secure choice for chemical plants that handle hazardous reactive substances, such as petroleum refineries. These valves can withstand the test of time and any chemicals they come into contact with because they are not made of elastomers or other materials that can corrode.

Triple offset butterfly valves are the safest option for withstanding water pressure, so water treatment plants can also benefit from their use. The triple offset valve's three offsets improve safety compared to valves with just one or two offsets, which run the risk of yielding under pressure. Rather than depending on one seat bearing the brunt of the pressure, the connected offsets and their geometric design work in unison to open and close.

A valve's capacity to protect your plant is its most crucial feature. A robust, effective valve can significantly reduce the likelihood of unexpected problems causing disruptions to your company's operations. The benefits of the Seat in the Body vs. on the Disc Edge and Spline Drive Stem to Disc engagement are also provided by the Triple offset, enabling stem and disc maintenance. The disc and stem are typically welded together. The best valves for ensuring effectiveness and safety in applications involving high pressure, extreme temperatures, and hazardous materials are JONLOO triple offset butterfly valves.