Diaphragm valves are made up of a diaphragm, a valve body with two or more ports, and a "weir or saddle" or seat that the diaphragm rests on to close the valve. The diaphragm valve was first created for use in pipe organs and industrial settings. The design was later modified for usage in the biopharmaceutical sector by utilizing materials that are compliant and resistant to sterilizing and sanitizing techniques. Furthermore, sanitary diaphragm valves are made to the highest standards specifically for use in the production of food and pharmaceuticals.

Table of Contents

- What is a Diaphragm Valve?

- How do a Diaphragm Valve operate?

- Types of Diaphragm Valves

- Wire type diaphragm valve

- Straight through diaphragm valve

- Diaphragm Valve Function

- Advantages of Diaphragm valve

- Disadvantages of Diaphragm valve

- Diaphragm Material Of Construction

Diaphragm valves are throttle valves that can be turned on and off in both directions. By limiting the region that media can enter and exit the valve, they effectively alter the speed and velocity of fluid flow. Because a thin, flexible membrane regulates the valve's opening and closing, these are known as "diaphragm" valves. They can be constructed from single-use materials, plastic, and metals like stainless steel. Similar to pinch valves, diaphragm valves press the thin diaphragm against the valve body using a linear compressor. They can be operated manually or automatically and provide both discrete and variable pressure control. Diaphragm valves are ideal for applications requiring stop/start fluid control at moderate pressures and temperatures because they are hygienic, leak-proof, simple to maintain, safe, and efficient.

Their function is similar to pinching a flexible hose to regulate the water flow through it. The flexibility of the diaphragm may make precise throttling challenging, but these valves are ideal for flows with solid particle matter, like slurries.

Weir-type diaphragm valves are the most widely used designs. Because the diaphragm and actuator are covered, the elevated lip/saddle configuration for limited flow control is perfectly appropriate and leak-proof. This design is appropriate for corrosive or hazardous gases and liquids because it prevents membrane disintegration. A weir is provided as an incorporated part of the valve body. In order to compress the diaphragm and prevent the surge, the weir acts as the valve seat. This valve is frequently naturally drained by the inclined body, albeit it can happen in both directions and for some purposes, that may not be ideal. This kind of diaphragm valve is typically produced in big sizes. Because of the higher weir, the diaphragm may travel less from its fully open position to its fully closed position, which reduces strain and stress on the diaphragm. Because viscous slurries and sediments can accumulate on either side of the saddle, the weir-type valve is frequently utilized for smooth, homogenous fluids. They are most frequently encountered in industries including food/chemical, gas processing, corrosive, and water applications.

The straight-through diaphragm valve resembles the weir-types in appearance, but it has a straight track instead of the usual saddle. Since the very bottom of the valve needs to be contacted, their membranes are often more compact and provide a greater passage distance. The diaphragm lifts high when the straight-through valve is open, allowing for maximum streamline flow in any direction. Even with coarse or fibrous debris in the line, the diaphragm provides a tight, positive seal when the valve is closed. These valves also need to be fixed because they typically have a shorter lifespan than weir-type designs due to their more compact membranes. Straight through diaphragm valves are frequently used for slurries, viscous oils, and other situations where blockage needs to be kept to a minimum. The full-bore style of valve is most frequently utilized in the beverage industry. It makes it possible to use steam or caustic soda for ball-brush cleaning without opening or removing the valve from the line. Because there is no saddle to prevent the abrupt change from input to outlet, they are also appropriate for bi-directional flow regimes.

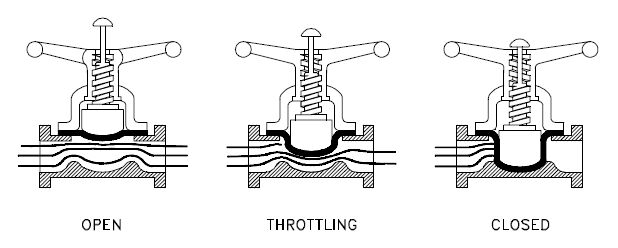

A stud that is molded into the diaphragm connects it to a compressor. The valve stem moves the compressor up to start or increase flow. The compressor is lowered and the diaphragm is forced against the valve's bottom to halt or reduce flow. Diaphragm valves can be fitted in any position and are great for regulating the flow of fluids that contain suspended solids. Weir-type diaphragm valves have the qualities of a quick-opening valve due to their huge shutdown region along the seat, which makes them superior at throttling compared to straight-through diaphragm valves. In order to prevent leaks between the body and bonnet cap, the diaphragm serves as the valve's gasket.

Diaphragm valves replace the valve plug components with a corrosion-resistant diaphragm and lined valve body. The diaphragm is moved to control the medium. The passage is opened when the diaphragm is raised, and the valve is closed when it is lowered and forced against the valve body.

- 1)straightforward design with just three components: a cover, a diaphragm, and a valve body.

- 2) Since the medium only makes contact with the diaphragm during operation, the valve is resistant to contamination..

- 3) appropriate for moving thick, caustic liquids

- 1) Unsuitable for pipes with greater diameters

- 2) Inadequate resistance to temperature and pressure

Many materials can be used to make diaphragms. Temperature, pressure, frequency of operation, and the type of material handled all influence the choice of material. At high temperatures, elastomeric diaphragm materials exhibit exceptional chemical resistance. At higher temperatures (over 150°F), however, elastomeric materials' mechanical qualities will deteriorate. The diaphragm can potentially be destroyed by high pressure. The concentration of the media the diaphragm will handle is another element that may have an impact on its performance. Up to a given concentration and/or temperature, the material may demonstrate enough resistance to corrosion from specified corrodents. The chart below shows examples of diaphragm materials and their specifications.

| Material | Size | Temperature | Applications | ||

| inches | mm | ºF | ºC | ||

| Butyl rubber | 0.6 – 14 | 15 – 350 | – 22 to 134 | – 30 to 90 | Acids and alkalis |

| Nitril rubber | 0.6 – 14 | 15 – 350 | 14 to 134 | -10 to 90 | Oils, fats and fuels |

| Neoprene | 0.6 – 14 | 15 – 350 | – 4 to 134 | – 20 to 90 | Oils, greases, air and radioactive fluids |

| Natural/synthetic rubber | 0.6 – 14 | 15 – 350 | – 40 to 134 | – 40 to 90 | Abrasives, brewing and dilute mineral acids |

| White natural rubber | 0.6 – 5 | 15 – 125 | – 31 to 134 | – 35 to 90 | Foods and pharmaceuticals |

| White butyl | 0.6 – 6 | 15 – 150 | – 22 to 212 | – 30 to 100 | Natural color, food, plastics and pharmaceuticals |

| Viton | 0.6 – 14 | 15 – 350 | 41 to 284 | 5 to 140 | Hydrocarbon acids, sulphture and chlorine applications |

| Hypalon | 0.6 – 14 | 15 – 350 | 32 to 134 | 0 to 90 | Acid and ozone resistant |

| Butyl rubber | 0.6 – 14 | 15 – 350 | – 4 to 248 | – 20 to 120 | Hot water and intermittent steam services, sugar refining |