The Emergency Shutdown Valves' Operation

During loading and unloading operations, emergency shutdown valves are an essential safety feature for vehicles carrying liquefied gas tanks. They are capable of the following:

1. Emergency Shutdown Capability: Emergency shutdown valves quickly step in to cut off the gas supply in the case of an accident, such as a leak or fire during the loading or unloading operation, reducing possible hazards.

2. Automatic Closure Mechanism: In emergency situations, such as fires, the fusible alloy component of the valve automatically closes when it reaches a predefined melting temperature, thereby carrying out self-regulated shutdown functionality.

3. Manual Override Feature: In addition to automated closure, emergency shutdown valves have manual control mechanisms that enable operators to manually close the valve in the event that an emergency requires quick action.

4. Overcurrent Protection Integration: Emergency shutdown valves have overcurrent protection mechanisms built in since they were designed with foresight. The valve immediately closes to protect worker safety and equipment integrity when it senses a flow rate inside the tank that exceeds predetermined criteria.

Classification of Valves for Emergency Shutdown

Emergency shutdown valves are divided into two main groups according to different driving mechanisms:

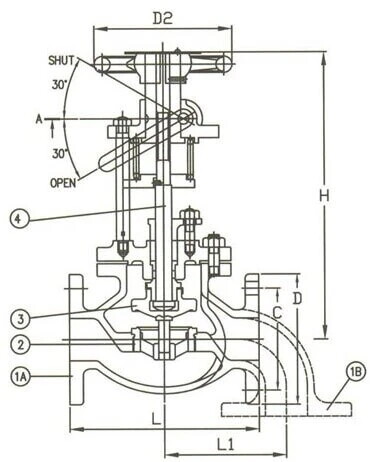

Electric emergency shutdown valves: These are powered by electric motors and control valve operation through power control. They are frequently equipped with remote operation capabilities, making them perfect for applications that require a high degree of automation.

Pneumatic Emergency Shutdown Valves: Powered by pneumatic systems, these valves are known for their quick response times and compliance with strict explosion-proof standards. They manage valve action by gas pressure control.

Using Emergency Shutdown Valves Properly

To guarantee emergency shutdown valves' effectiveness at crucial moments, they must be used and maintained optimally:

1.Pre-Operational Assessment: Before going live, make sure everything is operating as it should by carefully inspecting the components and valve integrity. Furthermore, it is critical to confirm the fusible alloy components' working status.

2.Respect for Operational procedures: During loading and unloading processes, respect for the established operational procedures is vital. Before disconnecting power or gas sources, operators must strictly adhere to procedure, opening the valve at the beginning of operations and closing it at the end.

3.Routine Maintenance Regimen: Emergency shutdown valves' operating strength is dependent on planned maintenance and upkeep. Regular inspections include examining the sealing surfaces of valves for wear or leaks and determining whether fusible alloy components can be replaced when necessary.

4.Precautionary Actions Compliance: When operating a valve, care must be taken to follow safety precautions. Maintaining a debris-free area around the valve, stopping activities right away when abnormalities are noticed, and making sure the valve closes and disconnects power or gas sources during idle times are all examples of preventive measures.

Essentially, emergency shutdown valves are critical components of industrial safety standards, and their careful installation and maintenance emphasizes their critical role in maintaining operational integrity and protecting worker health.