A Y strainer is a type of mechanical filter used in plumbing systems to remove unwanted debris or particles from flowing liquids or gases. It is typically installed in pipelines and consists of a Y-shaped body with a mesh or perforated screen inside. The name "Y strainer" comes from its shape, resembling the letter "Y."

The purpose of a Y strainer is to trap solids such as dirt, rust, scale, or other particles that could potentially damage or clog downstream equipment or components. As the fluid flows through the strainer, the screen or mesh catches the debris, allowing only the clean liquid or gas to pass through.

Y strainers are commonly used in various applications, including water supply systems, oil and gas pipelines, chemical processing plants, HVAC systems, and many others. They are available in different sizes, materials, and mesh sizes to accommodate specific requirements and prevent the passage of unwanted particles of various sizes.

Overall, Y strainers play an important role in maintaining the efficiency and longevity of industrial and plumbing systems by ensuring the smooth and uninterrupted flow of fluids while protecting sensitive equipment.

How does Y-Strainer work?

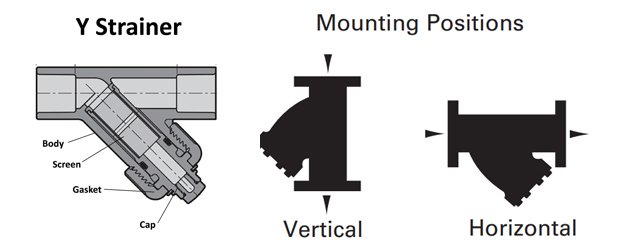

The working principle of a Y strainer is relatively simple. It consists of a Y-shaped body with an inlet and an outlet, and a removable screen or mesh filter inside. When the fluid flows through the pipeline, it enters the Y strainer through the inlet. As the fluid passes through the Y-shaped body, it encounters the screen or mesh filter.

The purpose of the screen or mesh filter is to catch any solid particles or debris present in the fluid. These particles are typically larger than the mesh openings, so they get trapped on the screen. Meanwhile, the filtered fluid continues its flow through the strainer and exits through the outlet.

Over time, as more particles accumulate on the screen, the flow rate may decrease. To maintain optimal performance, the Y strainer needs periodic maintenance. This involves shutting off the flow, removing the strainer cover, and cleaning or replacing the screen.

Do Y-Strainers Work Vertically?

Yes, Y strainers can work vertically. Y strainers are designed to remove unwanted particles or debris from fluid systems. They are typically installed in pipelines and can be oriented in either a horizontal or vertical position, depending on the specific application and space constraints. The vertical orientation allows for efficient filtration and easy maintenance, as the debris can settle at the bottom of the strainer for easy removal.

How to Clean a Y-Strainer?

Cleaning a Y-strainer is a relatively straightforward process. Here are the general steps you can follow:

1. Turn off the system: Before starting the cleaning process, make sure to turn off the flow of whatever liquid or substance the Y-strainer is filtering. This will prevent any accidents or spills during the cleaning.

2. Isolate the Y-strainer: Next, close the valves on both sides of the Y-strainer to isolate it from the rest of the system. This will prevent any fluid from flowing through it during the cleaning.

3. Remove the cap or cover: Some Y-strainers have a removable cap or cover that provides access to the filtering element. Unscrew or lift off the cap to expose the strainer element.

4. Remove the strainer element: Carefully pull out the strainer element from the Y-strainer housing. It might be a mesh screen or perforated metal cylinder, depending on the specific design. Take note of its orientation and position within the housing so that you can reassemble it correctly later.

5. Clean the strainer element: Rinse the strainer element under running water to remove any loose debris or contaminants. Use a soft brush or cloth to gently scrub away any stubborn dirt or buildup. If necessary, you can soak the element in a mild cleaning solution to dissolve or loosen any hardened deposits.

6. Inspect the housing: While the strainer element is removed, inspect the inside of the Y-strainer housing for any debris or residue. If you notice any, clean the housing with a brush or cloth.

7. Reassemble the Y-strainer: Once the strainer element and housing are clean, carefully place the strainer element back into the housing, ensuring it is properly aligned and seated. Reattach the cap or cover and tighten it securely.

8. Open the valves and test: With the Y-strainer reassembled, open the valves on both sides to restore the flow of liquid through the system. Monitor the strainer for any leaks or issues, and make sure it is functioning properly.

These steps are general guidelines, and the specific cleaning process may vary depending on the manufacturer's instructions or the type of Y-strainer you have. It's always a good idea to consult the product manual or reach out to the manufacturer for any specific cleaning recommendations.

Where to Use Y-Strainer?

Here are a few common applications where you might use a Y strainer:

1. Industrial processes: Y strainers are commonly used in industrial settings, such as manufacturing plants, refineries, power plants, and chemical processing facilities. They help protect equipment from damage caused by debris, such as rust, scale, sediment, or other solid particles present in the fluid.

2. HVAC systems: Y strainers are often used in heating, ventilation, and air conditioning (HVAC) systems to prevent contaminants from clogging or damaging components like chillers, boilers, pumps, or cooling towers. They ensure the smooth operation and longevity of these systems.

3. Water treatment facilities: Y strainers are employed in water treatment plants to filter out impurities like sand, algae, leaves, or other suspended solids before the water is distributed for various purposes, such as drinking water, irrigation, or industrial processes.

4. Plumbing systems: In residential, commercial, or institutional buildings, Y strainers can be installed in plumbing systems to protect fixtures, faucets, valves, or appliances from debris that may accumulate over time. They help maintain the efficiency and functionality of the plumbing system.

Remember that the specific application and requirements may vary, so it's always a good idea to consult with professionals or refer to the manufacturer's guidelines to determine the appropriate use and installation of a Y strainer in your specific situation.

Next: Y-strainer vs T-strainer

Previous: Valves for Seawater Application