Many industries utilize ball valves and plug valves to regulate the flow of gases and liquids. Both are appropriate for various applications due to their distinctive features and variations in design. This article examines the primary distinctions between plug and ball valves, including their design, purpose, benefits, and drawbacks, in order to assist in deciding which kind of valve is better suited for a particular application.

A plug valve is a quarter-turn valve that regulates the flow of liquids or gases using a tapered or cylindrical stopper. To open or close the flow passage, the plug rotates inside the valve body. Water treatment, oil and gas production, chemical processing, and pulp and paper manufacture are just a few of the industries that use plug valves because of their straightforward design and tight shutdown capabilities.

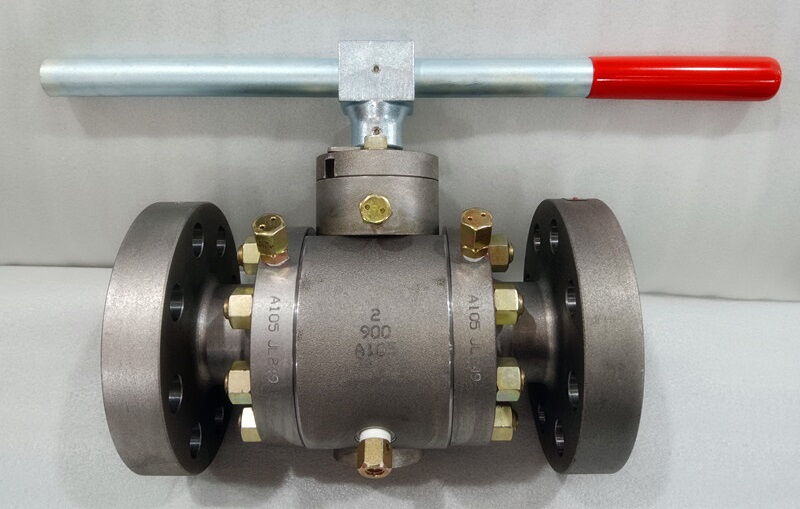

A ball valve is a quarter-turn valve that regulates the flow of liquids or gases by means of a ball having a bore. To open or close the flow stream, the ball rotates on its axis. Ball valves are long-lasting, durable, and operate quickly and effectively. They are employed in industrial process cooling, water distribution, and heating and cooling systems.

Plug and ball valves differ in the following aspects:

The plug valve is made up of a body with a parallel or tapered seat. This seat is compatible with a plug. The quantity of opening via the valve is determined by the position of an opening in the plug. Fluid can enter or exit the valve through these ports, which are apertures in the valve body. The stopper completely opens or closes the fluid flow when it is rotated 90 degrees. The plug valve can only operate in the completely open or closed state, and even though it has a quarter-turn, it is less effective than ball valves. Fluid flows through the valve when the plug's port lines up with the inlet and outlet ports. The smaller plug port size causes a pressure loss, though, which is a drawback when compared to a ball valve.

A quarter-turn valve known as a ball valve regulates flow by means of a hollow, perforated, rotating ball. Its straightforward design makes it simple to use and maintain, and the ball revolves inside the valve body to regulate fluid flow. The ball is connected to a valve stem. The bore is either open to the flow, allowing media to pass through, or closed, preventing media flow, when the valve stem is turned a quarter turn.

Quarter-turn valves, which include both plug and ball valves, close and open in response to a 90-degree rotation of their stem. The main function of these valves is shut-off. There are some distinctions between them, though.

Compared to a ball valve, the surface area used for sealing in a plug valve is substantially larger. Because of the enhanced sealing capabilities, more torque and operation effort are required.

Because ball valves require less torque, they are easier to use and weigh less. Although recent advancements in seal injections and chemical sealing solutions have successfully solved this issue, the reduced sealing surface in these valves may result in a sealing performance below that of plug valves.

Plug valves are categorized according to the shape of their plugs and whether or not they are lubricated.

- A lubricant film is intended to be present between the plug and the valve body in order for lubricated plug valves to function. By lowering friction and wear on the body and plug, this lubricant extends the valve's useful life and dependability. Additionally, lubricated plug valves provide better performance in high-pressure situations and tighter sealing.

Non-lubricated plug valves, on the other hand, don't need lubricant and are usually utilized in situations where the lubricant and the fluid being regulated are incompatible. In situations where a lubricant could be a source of contamination, like in the food and beverage sector, non-lubricated plug valves are also recommended.

- The plug's openings may be rectangular or spherical, among other shapes.

A number of factors are used to classify ball valves.

- Depending on the circuit function, it can be 2-way, 3-way, etc.

- Depending on the size and form of their bore, they can be full port, standard port, reduced port, or v-port.

- Floating or trunnion, depending on whether the ball is supported by a pivot or floats inside the valve body.

- 1,2,3-piece ball valves depending on how many body parts there are/

Regular maintenance is necessary for both plug and ball valves to operate at their best.

Plug valves' simple design and small number of moving parts make them easier to handle. The rest of the valve body is simply accessible for cleaning, and the plug is simple to remove and clean.

Cleaning is more difficult with ball valves. Accessing the ball or disc is difficult because it is located deep inside the valve. Debris from the medium may eventually build up in the ball valve's cavity, making cleaning and maintenance even more difficult.

When it comes to operation, plug valves are more economical than ball valves. Wear and tear on the valve body and plug is lessened when the plug in the plug valve fits snugly under the bushing. To preserve the valve's functionality and guarantee longevity, just swap out the bushing and top seal.

Plug valves' larger surface area and unhindered fluid movement make them appropriate for uses involving abrasive materials like sewage, mud, and slurries. When working with caustic materials, they guarantee a tight seal, and their anti-corrosive qualities make them a dependable choice for difficult applications.

Ball valves are a common option for automation, especially in sectors like field gas processing, LNG facilities, polymer manufacturing, and the transmission of natural gas and crude oil. They are also helpful in a variety of industrial settings, such as hydrocarbon processing, tank farms, oil refinery feedstock lines, and turbine and compressor skids. For further information, see our article on ball valve applications.

The plug valve's huge surface comes into touch with the medium, which raises the possibility of corrosion. The plug valve is also subjected to more wear when handling greater torque.

The characteristics of ball valves keep the medium from touching the disk. Over time, the reduced torque also lessens wear and tear. To learn more about designing a ball valve for corrosive environments, read our article on ball valves for corrosive media.

Plug and ball valves use a multipath functionality or a simple on/off function to control fluid flow. When deciding whether to utilize a plug valve or a ball valve, keep the following in mind:

- Because they provide flawless sealing and an easy-to-understand application structure, plug valves are the ideal option for delicate applications. They are also less expensive than ball valves. They result in a pressure decrease from the input to the outlet, nevertheless, and are not as compact as ball valves.

- For large, high-pressure applications that need to be operated more easily, go for ball valves. Though they have somewhat less sealing power than plug valves, they are more user-friendly and smaller.

A ball valve, for instance, would be a better option for a water treatment plant application that calls for controlling fluid flow because it can withstand high pressure and temperature applications and permits changes in flow direction. In a pipeline system including slurry, a plug valve would be more appropriate to control fluid flow because it requires less maintenance and permits a straight fluid flow. However, because of their straightforward, lightweight form and torque-free functioning, ball valves are more frequently utilized for cutoff applications. The characteristics of ball valves and plug valves are contrasted in Table 1.

Table 1: Plug valve vs ball valve

| Feature | Plug valve | Ball valve |

| Operation principle | Plug with an opening that controls flow through ports. | Hollow, perforated ball that pivots to control flow. |

| Sealing properties | Larger sealing area, better sealing, requires more effort and torque. | Easier operation, lighter, smaller sealing area, potentially less effective sealing than plug valves |

| Types | Categorized by lubrication and plug shape (rounded, rectangular, etc.). | Categorized by bore size/shape and ball support (floating or pivoted). |

| Maintenance | Easy to clean. | Difficult to clean due to deep-seated parts. |

| Cost | Less costly. | More costly. |

| Application | Suitable for abrasive materials like sewage, mud, and slurries. | Ideal for automation in industries like natural gas, oil, LNG, and plumbing. |

| Longevity | Less durable. | More durable. |

The particular requirements of your system will determine which valve is best for you. Consider the following:

- Pressure and Temperature: Ball valves are a superior option in situations involving high pressure or extremely high temperatures.

- Fluid Type: For slurries or extremely viscous fluids, use plug valves. For fluids that are clean or under pressure, ball valves are perfect.

- Maintenance Needs: If low maintenance is important to you, choose ball valves..

- Financial Restraints: Although plug valves are inexpensive initially, they may require more maintenance over time.

- Space Availability: Ball valves are more appropriate for cramped areas because they are smaller.

Due to their wider sealing surface, plug valves are better at sealing than ball valves.

Generally speaking, ball valves last longer than plug valves. This is due to the fact that as more fluids come into contact with the cylinder, plug valves are more likely to erode. Conversely, ball valves have more moving parts, use less torque, and come into touch with fluids less frequently.

A ball valve uses a ball with a bore to control the flow of liquids or gases, while an eccentric plug valve includes a plug-shaped, flow-restricting component that rotates in an eccentric direction.