A popular type of valve in industrial applications, the 3-way valve is identified by the number of ports it has. Owing to its inescapability in the industrial world, it is crucial to investigate the meaning, types, operation, and other noteworthy aspects of this gadget.

An industrial 3-way valve is designed for a variety of purposes, such as diversion, and has a consistent flow rate. Because of its three holes, which can be linked to tubing to allow for the flow of liquid or gas, it is also known as a multiport valve. These 3-way valve openings are available as one inlet and two outlets or as two inlets and one outlet. The connection application decides this.

In spite of being a multiport valve, the flow rate in each of the many valves stays constant. In every application where the valve is utilized, the liquid or gas is separated into two separate openings, but a consistent flow rate is maintained.

This valve's design permits one orifice to be open while the other is closed, or vice versa. This makes it simple to apply pressure using the device as a means of exhausting pressure from a single-acting cylinder or a valve actuator. Typically, three-way valves are either universal, closed, or opened.

The valve's mechanism enables it to offer a practical means of transferring the flow of gas or liquid from one location to another.

Additionally, the 3-way valve's cheap cost of operation enables its users to save money by doing away with the need for traditional gate valves and other appliances that are frequently found in steam generating plants. It not only replaces traditional three-way globe valves, but it also provides flow direction and shuts off control in a single valve body.

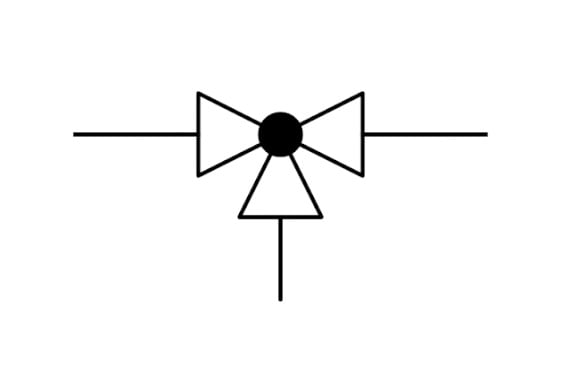

The 2 way ball valve symbol, which has a ball in the center of two triangles facing each other, is modified into a 3 way ball valve symbol.

The 3-way ball valve symbol consists of three triangles pointing in the direction of one another, with a ball in the middle. This proves that the valve can be generic if it doesn't specify the kind of 3-way ball valve that's there or it can be a symbol with a modifier if it does specify the precise kind of 3-way ball valve that's there in the water line.

- The existence of a valve in the piping and instrumentation diagram is indicated by generic valve symbols. That's the extent of it. The kind of valve that is there is not indicated by the general symbols. Instead, they depict a valve that will be utilized in the pipeline as being present in the diagram.

- As the name suggests, the modifier symbol in the piping and instrumentation diagram does more than merely show whether a valve is there. It even goes so far as to identify the precise kind of valve shown in the diagram that should be utilized in the pipeline.

Similar to other ball valves in the multiport valve family, the 3-way ball valve comes in many kinds. That's why getting to know them is crucial.

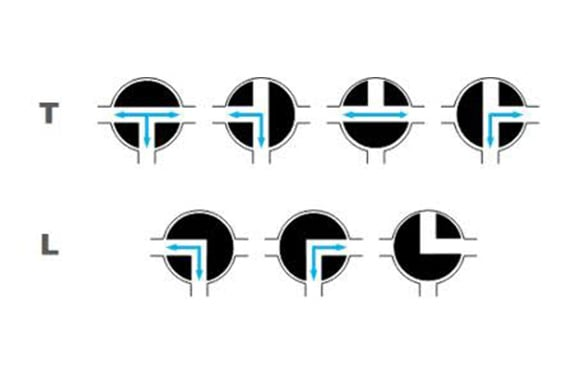

The T-port and L-port valves are the two main varieties of three-way valves. Their names derive from their shapes, and their applications rely on the job you want them to do. The 3-way ball valves' central aperture is denoted by the T and L forms.

Because of its T-shaped design, the T-port valve got its name. Another name for it is the 180-degree ball. Two intake flows can be combined into one outlet port using this kind of ball valve. It can also divide one input into two outlet flows, depending on the needs of the system.

Gas and liquid flows are frequently divided using T-port 3-way valves. The T-port 3 way ball valve can be used for splitting or mixing flow, diverting flow, and enabling a straight flow, depending on the system's requirements and the allowable range of handle motion.

Furthermore, the T-port valve can provide communication between the three channels in addition to providing flexible control over the medium's merging or diverging in the pipeline.

Different inlet and outlet flow patterns can be achieved by connecting the apertures of a pipeline using the 3-way ball valve T port. In most situations, the 3-way ball valve T-port valve is recommended over the L-port valve because it permits multidimensional flow patterns while the latter appears to be non-dimensional.

When the T-port valve is in one position, it guarantees a straight flow through the valve with little to no pressure loss and, when the position is changed, it diverts to a different direction.

With the three ports linked to the 3-way ball valve T-port valve, up to two paint sprayers can be used concurrently.

Unlike the T-port valve, it has the ability to stop, limit, or resume the flow. The valve handle can be adjusted in increments of 90 degrees; that is, it can be calibrated in 90, 180, and 360 degrees. That being said, there is only one direction it can go.

When drawing liquids or gases into a different pipe from many sources, the L-port ball valve comes in handy.

One type of 4-way valve that is used to verify flow when four pipes are connected to a valve is the double L-port ball valve. Additionally, there are flanged valves, which feature flanged ends that can be welded or bolted to any pipe for connection.

The L-port way valve is employed in situations when a diverter is required. This is so that flow from one main source to another can be redirected. Additionally, this valve facilitates easy pump switching, such as moving gas or liquid from one pump to another.

Furthermore, the L-port 3-way valve facilitates the redirection of flow from one storage tank to another, as well as from cooling to chilling.

The primary types of 3-way ball valves are the 3-way T-port and L-port valves, which also include the following:

- An open valve, in general, closes the stop orifice, the other port that permits flow from two. When the valve is open, fluid can pass through the body orifice on the left side of the valve and exit through the cavity port on the right side. This can also occur in reverse, meaning that, depending on the needs of the system, one orifice can be blocked and the other two turned into the inlet and outflow. There is always one opening in the open valve

- Closed valves often function in the same way as open valves. One opening (the body orifice) of a normally closed valve system is sealed up, leaving the other two (the cavity port and stop port) open. This permits flow via the valve, out the stop port, and from the cavity port.

Similar to an open valve, the system needs alter the input and outlet (the stop orifice can be sealed off to enable flow from the body orifice through the valve and out of the stop orifice). One orifice of the closed valve is constantly closed. - The normally open and closed valve and the directional control valve function somewhat differently. There are two flow ports available with the directional control valve. The body orifice directs the line of flow through the valve's body when the stop orifice is sealed closed.

It is significant to remember that a valve's design dictates the style and flow pattern within a system. It is impossible to overstate the benefits of the 3-way ball valve since it not only fits into any system but also serves multiple purposes.

Some of the many benefits of the 3-way ball valve are listed below.

- Has a simple structure with low volume.

- Is the most economical kind of valve available. This is due to the fact that it can carry out multiple tasks based on the needs of the system.

- Has low media resistance.

- Can mix up two distinct kinds of media because the valve has three ports.

- Considering that it has dependable sealing, it can change the direction of flow.

- Can divide the flow of any kind of media into two distinct paths.

- Has the ability to stop the flow of one medium while permitting the movement of another.

- Has several uses; it can be used to a variety of system requirements, including those involving high or low vacuum.

- Is capable of cleaning itself by removing debris from the sealing face and removing erosion to the seat brought on by high-speed fluid..

- Easily operated by quickly opening or shutting the valve. It can only be fully opened or closed by rotating 90 degrees..

- when the valve is fully opened or closed, has the ball and sealing face of the seat separated from the medium.

As mentioned before, the needs of the system have a major impact on how well a 3-way valve functions. Its functions will vary depending on the needs of the valve in the system in which it is used, given its broad range of uses. Among these are a few of the following:

- Cutting off a piping system's supply of liquid or gas (media).

- Opening the flow of liquid or gas in a piping system.

- Mixing of liquid or gas from two different pipes.

- Diverting flow of liquid or gas in the valve.

- Mixing of two different media in a piping system.

The 3-way ball valve offers piping application control, much as multi-port ball valves. Depending on the kind, its mechanism varies slightly since it operates by either turning a handle or activating an actuator (for 3-way electric ball valves, this is the case).

The multiport valve's internal ball rotates as a result, aligning the channels with the intake and exit ports to direct the flow of liquid or gas. There is variation in the range of motion of the handles according on their type.

By rotating the handle of the L-port 3-way valve 90 degrees, the mechanism enables the media to flow in a different direction. This indicates that because one port closes and another opens when the handle is twisted 90 degrees, the direction changes each time. The three ports cannot all be open at once due to the valve's operation.

Three ports can be open concurrently thanks to the 180-degree or T-port valve mechanism. With a T-port valve, media from two separate ports can be combined inside the valve's body and released out the other opening. Media can enter through two ports, exit through one, and vice versa thanks to the T-port shape.

In summary, the 3-way ball valve's mechanism is flexible and may be altered based on the type of valve being used and the needs of the system.

In industrial operations, valves, particularly ball valves, are crucial components. There are several ball valves available than the 3-way ball valve. Although there are other types of valves, the 3-way ball valve appears to be the most widely used due to its flexibility.

What distinguishes a two-way ball valve from a three-way ball valve, one would wonder? Do they differ from one another merely in name, or are there other distinguishing factors as well?

- An inlet and an outlet are the only ports and apertures that the 2-way ball valve possesses, which is the first and most obvious distinction between these two types of ball valves. It is very simple. The 3-way ball valve, on the other hand, has three ports, and depending on the needs of the system, any one of the three ports can be utilized as an input, an outflow, or both.

- Due to its two ports' restriction on the single straight media flow (i.e., from one end to the other without diversion or mixing of the media), the 2-way ball valve is limited.

However, the 3-way ball valve, which has three ports, is better suited for more intricate procedures that the 2-way valve is unable to complete. Additionally, the 3-way ball valve's operation permits mixing media inside the valve as well as changing the direction of media flow. - The 3-way ball valve is used for both directing the direction of media flow, mixing media, and shutting off the valve, whereas the 2-way ball valve is mostly used as a shut-off valve, also known as an isolation valve.

- When it comes to controlling the temperature and pressure of the media flow into and out of the valve, two-way ball valves perform better.

- Because the media flow in and out of the 3-way ball valve is uninterrupted once the handle is twisted and the channels line up with the valve's ports, it has a more steady flow rate than the 2-way ball valve. Conversely, the opening and shutting of a 2-way ball valve causes variations in the flow rate. The 3-way ball valve should be utilized in a system where water flows continuously.

- When using 2-way valves in systems that need for fluid mixing and diversion, additional accessories are needed. In situations such as these, the three-way ball valve will prove to be economical since it is capable of handling many tasks at once (mixing various media and changing the direction of the media flow).

- The 2-way ball valve is less expensive to purchase and install even though the 3-way ball valve is more economical. The 2-way ball valve is typically the preferred option for specific industries, particularly when it comes to controlling particular characteristics.

- The 2-way valve, which only has two positions (on and off), is used in situations where constant speed pumps are used. On the other hand, the 3-way valve, which changes the direction of fluid from inside the cooling coil to the outside, is effective in applications where secondary pumps with variable speed are used.

One would imagine that handles would be less useful for a 3-way valve given its flexibility. However, the handles have far greater significance than we realize. A handle provides the 3 way ball valve's power. The handle essentially determines how well the three-way valve operates.

Generally speaking, handles are attached to all ball valves to prevent them from turning too much. Because of the quantity of openings on this ball valve, handles are crucial. The handle's restricted range of motion gives control.

It is practically impossible to regulate the volume of media that passes through a 3-way ball valve without handles. When too much media passes through the valve and finally breaks down in the piping system, it will eventually become messy.

One of the most significant kinds of ball valves are 3-way valves, which perform a variety of functions in various systems throughout industrial operations. They are important components of a pipe and tube system for the movement of liquids or gases at various points in time.

Its mechanism, which fits into a variety of system needs and has been shown to be cost-effective, is a good example of adaptability since it allows the valve to perform multiple functions in different systems at the same time. Because of all its features, the 3-way ball valve is the perfect choice for industrial processes and their complexity. To learn more about it, get in touch with an experienced valve factory.